AUTOCAR. 15 May 1969

By EDWARD EVES

As a supplier who does almost 200 million (GBP) worth of business per annum with the British motor industry, it makes sense for GKN to sponsor a car incorporating the great range of components they manufacture. The basis chosen was a Lotus 47 and the engine a 3 1/2 litre vee-8 Rover. It was seen for the first time at the Racing Car Show.

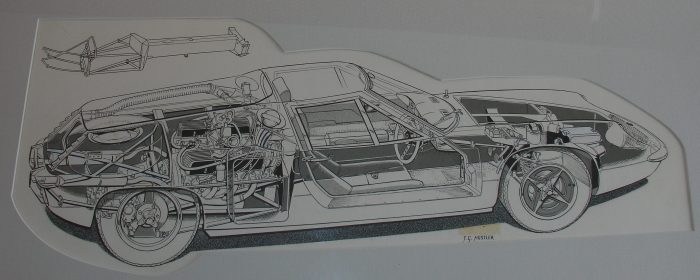

LOTUS built the car, basing the design on that of the type 47 racing Europa and powering it with a-Rover 3500 light alloy vee-8 engine driving through a ZF gearbox. The 47 differs from the Europa in having double wishbone suspension at both ends. This one has a suffix D – for Different, we like to think.

The difference starts with the chassis frame, which, although of the Europa large box section back bone type is some 10 in. longer then standard. Rear suspension is pure formula 1 with reversed lower wish- bones and adjustable single-tube top links; long double trailing arms, picking up with, the extremities of the backbone, provide longitudinal location. Light-alloy cast wheelposts are used; in common with the front wheelposts, the wheels and the bronze, cared wheel nuts are products of Kent Castings Ltd of the GKN Castings sub-group. Front suspension is reminiscent of the type used on the Lotus 23 and 33, with welded tube wishbones. Armstrong co-axial coil spring and damper units are used front and rear. Vandervell Products racing department, who built the Vanwall racers, made the front and rear roll bars.

A welded tube space frame (which is, in effect, two steel tube tripod with their bases "standing" on the arms of the rear cross member) forms a rear chassis extension. It supports the rear ring bulkhead to which the suspension is attached. This bulkhead also acts as a rear engine and gearbox mounting point. The front engine rnountings are attached to brackets welded to one leg of each of the tripods close to the engine bulkhead.

Steering is by a rack-and pinion mounted on the leading face of the front cross member. The steering column is adjustable for length and incorporates an impact absorbing section; the 14 in. dia. steering wheel has a leather covered hard rubber rim.

Girling disc brakes are fitted on all four wheels, the front and rear systems being separate not only for safety masons, but to enable the front-to-rear balance to be adjusted by means of a balance bar between the appropriate master cylinders. The whole assembly, including the brake and clutch master cylinders and the accelerator pedal is carried on a very neat bracket-cum-tray which bolts to a pair of lugs welded to the top face of the front cross-member.

A Rover vee-8 was the obvious choice as a power unit because it is not only light in weight and of the right configuration but it also incorporates a good proportion of GKN products. For example, BKL Alloys, who supply the IM 25 alloy for the cylinder head and block are a GKN company. GKN Forgings make the connecting rods while GKN Screws and Fasteners produce the push rods, the rocker pad inserts and the carburettor damper pins. Birfield Filtration make the pressure-relief valve filter. All the engine fastenings, including the connecting rod and cylinder-head bolt are GKN products. as are a number of special titanium and very-high-duty bolts and their associated nuts. And, of course, Vandervell Products supply all the engine bearings, including those for the camshaft. Internally the engine is standard. Externally it is notable for the twin SU HD8 carburettor installation on a manifold similar to that of the Rover P6BS mid-engined sports car; a Weber installation utilizing four 45DCOE Webers will be tried at a later date. However GKN have not adopted the clever equal pulse exhaust system invented for the BS, preferring a simple duplex system with each bank of cylinders feeding into a separate header before passing through a large capacity absorption silencer. With the SU installation, power output is 185 bhp (net) at 5,200 rpm.

Engine cooling is provided by a pair of forward mounted ducted radiators connected in parallel with the cooling water feed shared between the radiators after passing through a swirl pot to remove aeration and steam. Pipes running below the chassis backbone carry coolant to and from the radiators. To prevent overheating in traffic, thermostatically-controlled fans with an over-ride switch, are mounted on the front faces of the radiators. In view of the engine location, an oil radiator was deemed desirable and is mounted In the engine compartment and provided with a special air duct.

Power is transmitted by a 7.25 in. two-plate Borg and Beck clutch is incidentally has GKN forged pressure plates the five-speed (four synchromesh speeds) ZF 5DS--NR2 gearbox which is mated to the engine by means of a special clutch housing cast by Kent Alloys. Fixed-length drive shafts fitted with GKN Birfield's new sliding constant velocity joints (at the inboard ends) and Hooks joints transmit the drive to the wheels.

Fuel is drawn from two 9-gallon [Imp] tanks mounted in the body valance aft of the firewall. They are permanently connected by a cross feed, the main feed being from the left hand tank to the carburettors through an anti-vapourization constant-flow system which spills back into the right-hand tank.

In common with the rest of the car the glass-fibre body resembles that of the Europa but is in no way Interchangeable with it. The rear "sun dock" is higher than that of the Europe and the rear quarters feature interior air exteriors connected by flexible pipes to the cabin. A hinged cover gives access to the spare wheel, which is mounted in a cradle over the gearbox, releasing the front compartment for luggage stowage.

GKN-Sankey have produced specially styled bumpers. Tinted glass is used throughout and there an electric side window as on the standard Europe S2.

All in all, the GKN Lotus 47D Europa is one of the most interesting specials to come along for some time. There is no reproducing it unless, of course, you are a multimillionaire.

Return to the 47D page

Return to the main car page

Return to the main photo page

Return to click Ben's Home page

Please send any comments, suggestions, complaints to seven+47@47d.org